Revo Testing Technology is excited to announce that Darryl Tompkins, Revo’s Chief Technology Officer, will be presenting URTeC:2515, An Examination of the Effect of Surface Data Acquisition Methods on Well Performance Evaluation and Completion Optimization, on Monday, July 20th at 10:45 am CST.

The Unconventional Resources Technology Conference will be held online from July 20th to July 22nd 2020, and Revo Testing Technologies will be presenting under Theme 7: Common Unconventional Focuses EOR Session.

Please visit the URTeC site, https://urtec.org/2020, for more information about technical sessions and registration.

Darryl’s presentation will discuss four case studies from the paper that illustrate how good data is critical for an engineered flowback because it reduces ambiguities in assessing the effect of choke changes on well performance and reduces the timeline for assessing the effect of changing completion designs on well performance.

When asked what the most important take away is from the paper Darryl said:

“It is essential that the production team has the right people and equipment in place to consistently collect high-quality data.”

We look forward to discussing this further at the URTEC.

In the meantime, if you have any questions about how you can improve your data quality please reach out to info@revotest.com.

Please see the full abstract for URTeC 2515 below. We will update this blog with a link to download the paper when its available online.

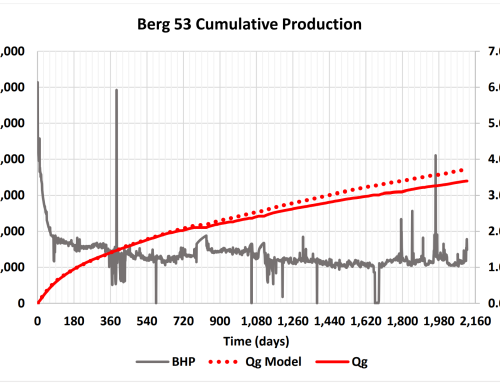

“It is a common practice in the development of unconventional wells to change completions designs to determine which design works best in each area. Quite often a Rate Transient Analysis (“RTA”) of the flowback / early production data is used to evaluate how well performance is affected by changes in the completion design. Many analysts faced with performing RTA struggle to have confidence in the analysis results due to poor quality production data. This paper shows how different surface data acquisition methods affect the evaluation of well performance using common RTA techniques. Additionally, this paper will recommend preferred methods of data acquisition and demonstrate how these methods produce less ambiguous results.

Examples of early production data are shown that were acquired from a variety of common sources found in production operations. Practical measurement QA/QC methods are used to evaluate data quality, and RTA is used to demonstrate the effect data quality has on the well performance evaluations. Comparisons of results will be used to illustrate the impact that good and poor quality data can have on evaluating the relative difference in well performance due to changes in completion designs.

Superior data quality should be a top priority if a well’s performance and/or completion design needs to be evaluated quickly and accurately with RTA of the early production period. Some data acquisition methods shown in this paper are not adequate for collecting the quality of data needed to produce reliable analysis results. Frequently, the changes from one completion design to the next are relatively small. With poor quality data, it can be impossible to quantify the effect of these changes. Examples presented in this paper show how poor data quality can be misleading when it comes to well performance evaluations. Examples of data acquisition from some of the best quality sources illustrate how straight-lines used on specialized diagnostic plots can match the data very closely. This gives the analyst much more confidence in the magnitude of the difference in well performance due to changes in the completion design.

Iterative completion optimization can be a waste of time and money if the difference in a well’s performance due to changes in the completion design cannot be evaluated quickly and accurately. If those responsible for unconventional well performance optimization are going to continue to rely on the insights provided by RTA, it seems only logical that the data going into the analysis needs to be of the highest quality possible.

Reservoir and production engineers need high-quality data to evaluate a well’s performance so that they can provide feedback to the completions engineers on which changes in the completion design have the largest impact on well performance. None of this can be done properly if the production team does not receive the best quality data available. The production team must have the right people and equipment in place to consistently collect high-quality data. This often seems to be an overlooked component of the overall value chain.”

Leave A Comment